What are bioplastics?

Earlier this year, the UK government announced a climate emergency, acknowledging that the world must reduce its contribution to greenhouse gas emissions abruptly or face serious environmental damage in the future. Following this announcement, along with many other eco-friendly moves by the government, public awareness of environmentalism has erupted. One aspect of reaching the UK’s new target of being zero-waste by 2050 is the shift from oil-based, non-biodegradable plastics to bioplastics.

Bioplastic is the name for a range of plastic products made from renewable, natural materials such as starch from corn or wheat. These products have a number of environmental benefits but are not commonly used in many products as their production is still expensive compared to traditional plastic.

Plastic production impacts

Plastic is a highly versatile substance used almost everywhere worldwide but its history is only a short one. The first plastic to be made from fossil fuels was invented in 1907 and since then, the world has been producing millions of tonnes without consideration for how long it will take to break down and little attempt, until recently, to recycle it.

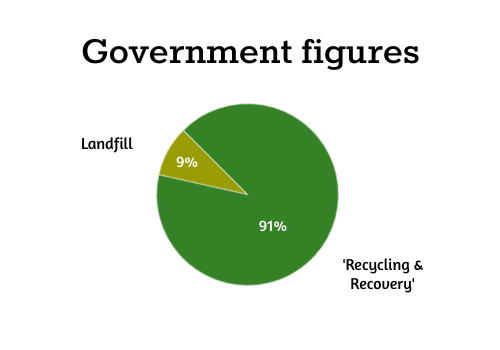

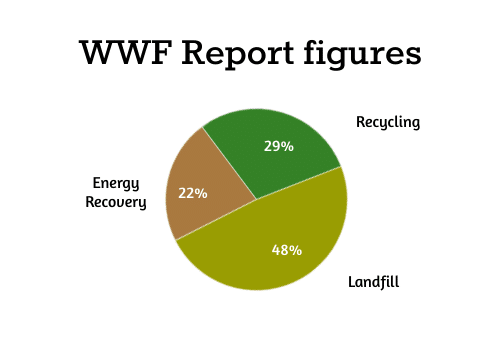

Over 2 million tonnes of plastic packaging is used in the UK alone each year and a World Wildlife Foundation report estimates that 48% of plastic waste in the UK is sent to landfill. That’s roughly 1 million tonnes of single-use plastic packaging being left to pollute the earth for hundreds or thousands of years.

All waste sent to recycling, even the batches rejected for contamination, have been included in the government figures. This makes them seem much better than they are and makes the data misleading.

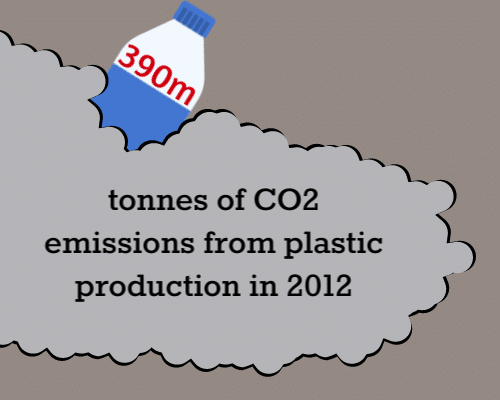

Not only is the crude oil used to make plastic a finite resource which will soon be completely used up, but if plastic usage continues at the same rate of growth, greenhouse gases from the global plastic sector will also account for 15% of the global annual carbon budget by 2050. It is in the UK’s best interest to look elsewhere for natural plastic alternatives which can be created renewably and can reduce emissions drastically.

Examples of bioplastic types

Though many recognise the need to stop using non-renewable oils to produce plastic, there are those who have also voiced their concerns for just how environmentally friendly bioplastics are. As a company dedicated to reducing our environmental impact and tackling the damage of single-use plastic, we’ve decided to take a look at the different kinds of bioplastic and how they are used.

PLA

One of the most promising bioplastic options and the one we use in our cups, lids and straws, PLA is a bioplastic produced from the fermentation of corn, wheat or sugarcane. This type of plastic has lots of applications as it resembles petrochemical plastic. It can also be processed in the same facilities manufacturing oil-based plastics, meaning no new investment is needed.

The production of PLA produces around 70% fewer greenhouse gases when it degrades and saves 2.3 times the energy to make, showing massive savings for the environment. However, it still doesn’t have the universal applications of oil-based plastics, as it has a melting point of around 60 degrees Celsius unless combined with other polymers.

Thermoplastic Starch

Thermoplastic starch currently makes up 50% of the global bioplastics market. This type of bioplastic is waterproof so has uses in food packaging, cutlery, coated cardboard and nappies.

Usually derived from potatoes or corn, this is another material which can be shaped into many different forms with multiple applications to reduce the number of petrochemical plastics used in packaging.

PHB

PHB is a bioplastic which is both bio-derived and biodegradable and can be broken down into water and carbon dioxide by microbes found in soil. It’s produced by bacteria which break down glucose or starch before having their nutrients restricted. When the nutrients are restricted, the bacteria form long chains of carbon which imitate the same chains that form regular plastics.

There have also been tests using PHB for surgical applications as some forms are bio-absorbable. This means that the plastic can be shaped into stitches, pins or sheets to heal the body which are then reabsorbed without the need for removal.

PA 11

PA 11 is a bioplastic made from castor beans, meaning it’s a renewable product which produces fewer greenhouse gases. However, the plastic created is not biodegradable. Products made from PA 11 will break down at the same rate as regular plastic, potentially polluting the land and sea.

This type of bioplastic has been in use for decades, forming car fuel lines and brake tubing as well as being used in trainers and some surgical equipment.

Polyethylene (PE)

Polyethylene is the most common type of petrochemical plastic produced for packaging. However, scientists have been able to produce this same polymer using natural products like sugarcane and corn.

Making plastic from natural products has the benefit of not wasting finite resources but doesn’t help solve the waste and pollution issues with long-life plastics like polyethylene. The plastic produced can be recycled, however, so by improving recycling rates, this process would help to cut emissions and the harmful damage plastic has on the environment.

Is bioplastic better than plastic?

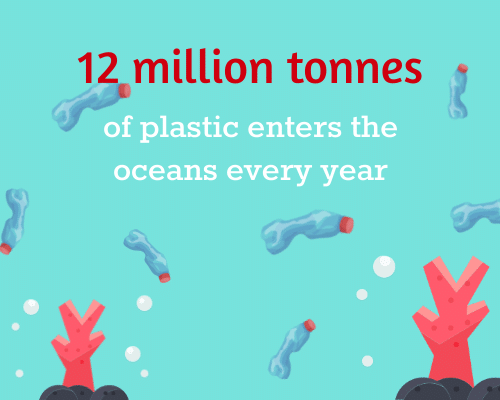

Globally, the issue of single-use plastic is causing untold damage to our earth and seas. The threat of the oil used to make them finally running out means that, even beyond their environmental impact, plastic companies will need to invest in alternatives to survive.

At first, bioplastics may seem like an easy, green alternative to regular plastic, but current production methods are filled with complications which have caused some campaigners to question just how eco-friendly they really are.

'Biodegradable'?

Biodegradable plastics (made from traditional petrochemicals) typically don’t break down as easy as they should. All plastics are technically degradable but regular plastic takes hundreds or thousands of years to fully break down, which is why it’s causing such a problem.

Many plastic products sold as biodegradable are actually only able to be properly broken down in specific settings, for example using industrial machines or at a certain temperature. Some other plastics are broken down over time by light or water. Understanding exactly how each plastic needs to be disposed of to correctly be broken down can be hard to remember and could make it more difficult for consumers to support eco-conscious treatment of plastic packaging if it were to be used in mainstream production.

Some bioplastics are also combined with other polymers to give them stronger properties. When broken down, these products can leave behind harmful residue or microplastics which can then reach the ocean or human drinking water. This can then be dangerous to animal and human health, meaning that any environmental successes which come from producing cleaner plastics are negated by their end of life treatment.

Recycling power

Some bioplastics and most regular plastic can be recycled into new products, allowing them to have much longer lives and reducing the amount of single-use waste being disposed of. However, this process can sometimes use more energy than producing new products in the first place, inadvertently emitting more greenhouse gases.

To ensure plastic recycling results in environmental savings, the entire system will need to be improved to find ways of producing recycled materials using less energy and generating more renewable energy in the first place.

Other environmental contributions

While bioplastics help to reduce our need for oil, leaving valuable resources in the ground and keeping their negative environmental impact locked up, they can also cause problems of their own. It is imperative that the global plastics market reduces its contribution to carbon emissions and the pressure on finite oil resources but companies will need to carefully consider the alternative contributions from other products.

Some common issues with bioplastics include:

- Breakdown produces greenhouse gases

Bioplastics made from plant products, such as PHB, are easily broken down domestically into carbon dioxide and water. Though this is beneficial as the products are easily removed from the ecosystem, carbon dioxide is a greenhouse gas absorbed by the plant products as they were growing. This means that, though growing more plants for plastic will initially help to reduce carbon dioxide in the air, its breakdown will still release the same amount.

Other starch-based bioplastics can produce methane if left to break down naturally and not processed properly. Methane is a greenhouse gas 23 times more potent than carbon dioxide.

- Corn and maize used to make plastics takes some food agricultural land away

Many bioplastics are created by processing food products like corn, maize and potatoes. Though these are easily accessible, cheap and renewable, they are a staple food source on every continent. By increasing the demand for bioplastics, more land dedicated to the production of essential carbohydrates will be focused on plastic production. This will likely affect the poorest societies around the world who are also expected to feel the worst effects of climate change.

- Confusing terminology could frustrate efforts to recycle normal plastic

With so many different kinds of bioplastics already on the market all needing to be disposed of in different ways, this puts a lot of pressure on consumers to remember the rules for every type of plastic and ensure everything is done right. As petrochemical plastic recycling is becoming more common and standardised, the introduction of a range of plastics could jeopardise the progress being made.

Promising alternatives

Though bioplastics at the minute are still not a perfect solution to plastic waste, there are innovative researchers around the world finding new, more eco-friendly ways to produce bioplastics and reduce dependence on fossil fuels.

Wastewater plastics

Students at Columbia University, led by Kartik Chandran was successful in using wastewater to convert organic carbon into fatty acids which could then be used to produce PHA. Chandran also believes that this process could be used on food waste or human waste to make the process more concentrated, saving money and maximising production.

This plastic-producing process would also be effective at reusing as much organic material as possible and tackling food waste issues globally.

Food packaging innovation

Algae plastic

Scientists at Michigan State University have genetically modified cyanobacteria, or blue-green algae, to constantly naturally produce sugars which can then be consumed by plastic-producing bacteria. This would allow plastics to be created without consuming so much food product, helping to cut costs and land use.

The future of bioplastics

Scientists around the world are looking for creative alternatives to plastic, often also focusing on how waste can be used to help promote a cyclical process and reduce waste contributions in general. While none of these products is completely ready to enter the mainstream yet, it’s only a matter of time before bioplastic production is ramped up.

When considering the whole process of farming, production, processing and disposal, bioplastics have a long way to go before they are fully cost-effective and eco-friendly versus their non-bio counterparts. However, the innovation in the industry is promising and shows that, with a green-focused overhaul, plastic won’t always be a harmful drain on our planet’s resources.